A robust manufacturing system cannot exist in the United States unless we have control over the pillars of the industry: Raw materials and the capabilities to transform them into usable products at commercial scale.

This is exemplified in the engineering of metal products, which are essential to the largest and most important industries on our planet. From the critical components that go into jet engines and compute infrastructure, to consolidated, complex parts for medical or industrial machinery applications, precisely engineered metal products are key to the massive, multi-trillion-dollar markets that the U.S. economy and national security depends on.

But with notable supply chain, labor, and infrastructure limitations, we can’t simply revive traditional American manufacturing — we have to reinvent it with advanced technology.

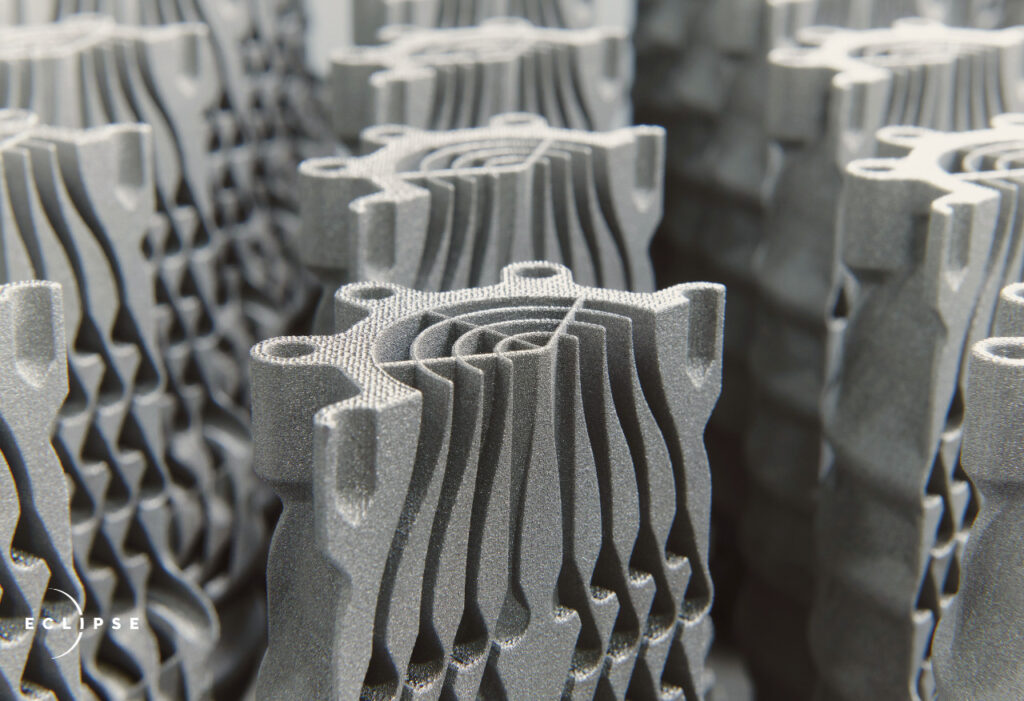

VulcanForms is leading this mission with its digital manufacturing ecosystem that uses advanced hardware, physical AI, metallurgy, and automation to transform raw materials into in-spec, compliant, and fully-tested products for industries ranging from aerospace and defense to medical and consumer electronics.

As organizations across the U.S. race to reduce their reliance on foreign suppliers of critical minerals and scale domestic manufacturing capabilities, demand for VulcanForms’ services has skyrocketed. In 2025 alone, the company landed several multibillion-dollar commercial agreements spanning medical devices, defense technology, and consumer products, and is on track to begin shipping qualified and in-spec metal products for these customers in the second half of 2026.

To meet that soaring demand and further scale their operations, VulcanForms has raised $220M in Series D funding. VulcanForms will use the capital to expand its team and digital manufacturing footprint (the first such facility in the U.S.), enabling the company to significantly deepen its existing partnerships and serve an increasing range of new customers. As committed partners to the company since the very beginning, Eclipse is proud to be co-leading VulcanForms’ latest round with 1789 Capital.

VulcanForms has become an indispensable partner to a growing base of top-tier customers across each industry vertical it serves, because the benefits are multi-faceted. The company’s vertically integrated platform (which combines additive and subtractive metal manufacturing) can deliver finished products end to end upwards of 30x faster and at 10 percent of the cost of other advanced metal manufacturing systems. Moreover, the VulcanForms system is a considerably simpler alternative to traditional manufacturing. The ecosystem requires minimal human labor and no additional tooling, allowing for more freedom in manufacturing while collapsing the supply chain down to raw metal feedstock and electricity. This eliminates the complexity of multi-party supply chains, and delivers an attractive margin structure for customers. Collectively, these benefits are establishing VulcanForms as the TMSC of manufacturing.

Having worked alongside the company since its founding in 2015, it’s been incredible to watch VulcanForms evolve from a pioneering innovator into an industrial-scale production enterprise leading the next generation of American manufacturing. We’ve been especially thrilled to see VulcanForms’ trajectory under CEO Kevin Kassekert — a renowned leader who scaled Tesla’s famous gigafactories and cross-country supercharger network and built Redwood Materials into the world’s only vertically-integrated, closed-loop battery recycling, material refining, and energy storage platform.

As one of the only providers of advanced digital metal manufacturing services in existence, VulcanForms has always been an outlier. Now, the combination of unparalleled technology and Kevin’s experience scaling next-generation businesses in complex physical industries has the company on track to be its own category: The backbone of American industrial infrastructure.

Follow Eclipse on LinkedIn or sign up for Eclipse’s Newsletter for the latest on building the New Economy.