When a robotics hardware startup recently shut its doors, it wasn’t long before I heard the same old refrain: “Hardware is hard,” delivered with a shrug and a nod of resignation.

We should be past this mindset by now. Knee-jerk dismissals of so-called “hard” tech shouldn’t be happening at a time when startups developing physical AI and other software-driven hardware solutions are making astounding progress, especially in the last year. One company’s struggles cannot be viewed as an indictment of all technology involving hardware when there is real, tangible proof that we are living in a new era: More startups than ever are answering the national call to reinvent our industrial base, and they are no longer selling a vision of the future — they are showing us, today, what the next generation of physical industries looks like in the form of game-changing defense technology, modernized energy infrastructure, advanced manufacturing and construction platforms, and much more.

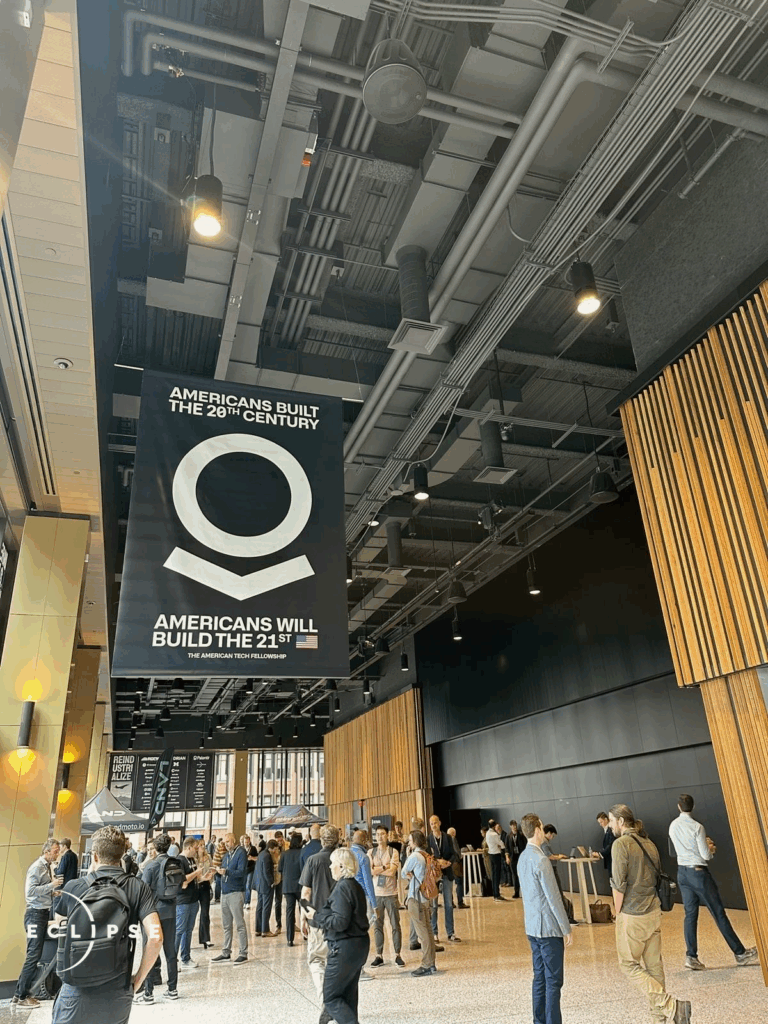

Silicon Valley needs a collective mindset that matches what we saw on display at Reindustrialize last month: The pragmatic optimism that we actually can reinvent physical industries and create great businesses in the process. The event was buzzing with positive energy to leverage integrated hardware and software to take on America’s biggest industrial goals, as daunting as the challenges are (i.e. maintaining national security leadership in the face of increasingly sophisticated and hostile adversaries, reducing our dependence on foreign supply chains, reversing the decades-long decline in our capacity to build and manufacture everything from ships to nuclear reactors to medicine). These are hard problems with hard, but not impossible, solutions. Here’s what that looks like in practice:

- Reinventing Domestic Manufacturing: One of our toughest and most foundational problems is creating the most opportunities, and each part of the manufacturing ecosystem needs innovation and investment. Automation and decentralized production capabilities (including tools to mitigate supply chain constraints) are a critical part of the effort. VulcanForms, which provides an additive manufacturing platform and precision machining service to cut down reliance on international supply chains, is serving a critical role within that ecosystem. During his presentation, VulcanForms CEO Kevin Kassekert pointed out the next phase of domestic manufacturing likely won’t look like that of previous eras, but as a network of distributed, specialized, and highly automated production hubs strategically located next to one another and to end customers.

In the U.S., skilled labor is a major bottleneck to building and manufacturing everything from semiconductors to satellites. Developing human-like automation capabilities is imperative. Recently, Eclipse co-led the investment in Genesis, which is developing a universal robotics foundation model that will do for physical AI what large language models did for digital AI. This will be a crucial unlock to infuse human-like intelligence into physical machines.

- Energy: Our energy needs are rapidly expanding, fueled by the rise of AI and data centers, and advanced manufacturing centers we are developing down the line. Nuclear power was examined from an economic, policy, and environmental angle at Reindustralize, with the firm conclusion that it represents the greatest opportunity for both industry transformation and a safe, sufficient source of power. We recently invested in The Nuclear Company, which is modernizing the deployment process with a design-first, build-many approach. TNC’s CEO Jonathan Webb gave an impassioned presentation at Reindustrialize, detailing how the company’s partnership with Palantir and close collaboration with regulators is allowing TNC to move quickly on their mission.

We’re also proud to work with entrepreneurs who are using electricity to transform various parts of the transportation and shipping industries. Arc is on a mission to electrify the entire marine industry, building battery-powered boats that are less expensive to run and maintain — as well as being cleaner and quieter.The company, whose team hails from SpaceX, Tesla, Rivian, and marine industry primes, has moved quickly since its founding in 2021. By solving the key technical unlocks for the entire system and launching their consumer-grade boat Arc Sport, the company got a foothold into the industry and has been able to iterate extremely quickly since. Recently, Arc opened its R&D facility for commercial-grade workboats and has multiple vessels at work in various stages, said Arc CEO and Co-Founder Mitch Lee.

“We’re not wasting time. We compounded all of our learnings from our consumer product into our commercial efforts,” said Lee. “We’re starting with tugboats, and from there we can move onto ferries, pilot boats, coast guard, you name it. This is just chapter one.”

Meanwhile, Rivian spinout Also is building a vertically integrated micromobility platform that underpins a variety of electrified form factors for different use cases, geographies, and price points.

- Construction: From data centers and energy infrastructure to manufacturing facilities and roads, everything needs to be built into existence. Physical AI can play a huge role in helping us meet these goals. We were thrilled to incubate and invest in Bedrock, which is developing autonomous technology for heavy machinery and officially launched at Reindustrialize.

- Defense: As described by numerous current and former military officials at Reindustrialize, our adversaries and peer competitors have been focused on adoption of cutting-edge military and dual-use technologies. While there is no shortage of areas where U.S. defense capabilities are unmatched and continue to innovate, the country has not kept pace in certain critical areas like shipbuilding and space-to-space conflict. Eclipse is proud to back startups working to reverse this trend. We led the seed round in Blue Water Autonomy, which launched out of stealth this spring to modernize the marine industry by developing autonomous ships, starting with development for the Navy. We’re also thrilled with the progress by True Anomaly, which has hit several major milestones towards developing a holistic hardware and software platform exclusively focused on establishing U.S. space superiority, and propulsion startup Ursa Major, which recently landed a major contract with Stratolaunch to develop and deliver its Hadley engine.

Lately, there’s been a surge of excitement for defense companies in particular. If this means we enter into hype cycle territory, that might not be the worst thing, said Anduril CEO Palmer Luckey.

“Hype is bad if you let it break your rational thinking and end up playing yourself by thinking it will be easier or faster,” said Luckey during Reindustrialize. “But hype is also what allows you to get investment in iteration cycles, and there is enormous power in optimism. If people in the industry can’t be excited about it, how can private markets be expected to follow?”

In fact, national-scale excitement over the opportunity to reinvent our industrial base is what will take us to the next phase. It’s happened before. Immediately after World War II, physical sectors in America underwent a massive wave of innovation and expansion, firmly establishing the country as an economic and defense powerhouse. We need a similar level of collaboration across the public and private sectors to create the next golden era of industrial evolution, ensuring we maintain our global leadership and national security.

There’s no way to grow our GDP or strengthen the U.S.’ energy backbone without doing the tough stuff —and the effort needs to come not just from the founders building the new economy with integrated hardware and software, but from the wider financial and government ecosystem. It shouldn’t be easier to get regulatory approval for crypto products than for new factories. It shouldn’t be easier to find top-tier talent to develop and train the digital agents (which may someday replace them) while we are short millions of people to build the data centers and energy infrastructure powering the AI revolution. It shouldn’t be easier to raise money for a video-generating app than it is to raise money to develop and manufacture defense technology in an increasingly hostile world.

The startup ecosystem is still heavily indexed on companies that invent new tech in search of a problem to solve, rather than companies that set out to solve a longstanding problem. Of course they don’t fit an academic stereotype of lean, zero-marginal-cost software, or the traditional early-stage financing models because of the “J-curve” cash flow profile. But as they push beyond the tough moments (which all startups face) companies developing integrated hardware and software create real value, real resilience, and real jobs. Don’t lose sight of the fact that startups targeting massive physical industries have the potential to become much, much bigger businesses than any purely digital company — just look at the most valuable companies in the world today.

This is why we need to abandon binary definitions of easy and hard companies. Building any successful company is hard. We need to revalue the kinds of companies and technologies that build the physical systems our society runs on — transportation, energy, defense, logistics, manufacturing, healthcare, and on. These are the platforms of the real economy. They need software, and they need hardware. And they need bold visionaries to build them. Not tomorrow, but today.

Shortly following Reindustrialize, President Trump and Congress passed the “Big Beautiful Bill.” and policymakers must focus on targeted action to rebuild our industrial primacy.

Here are three priorities:

1. Restore Industrial Permitting Sanity

Today, it’s faster to build a software product than to get a permit for a factory. That has to change. We need a permitting system that distinguishes between industrial progress and environmental harm — one that clears a path for strategic manufacturing without sacrificing oversight. Reforming NEPA and modernizing local zoning and siting laws are essential steps.

2. Back Strategic Sectors with Smart Financial Support

In addition to semiconductors, we should identify other high-leverage sectors — robotics, advanced materials, nuclear energy, agricultural tech — and invest accordingly. That investment support can take many forms which do not have to be direct government subsidies. In many cases, in sectors like mining and defense, conditional government contracts — stipulating that the government will be a buyer at a determined price level if the company is able to deliver — are enough to allow companies to raise private sector capital with no upfront government funding commitment or subsidy.

3. Train the Workforce we Need

For decades, China took U.S. innovation and focused on execution and deployment while we outsourced production deemed too “low margin”. Now China is the innovation leader in many areas like materials science and advanced manufacturing — in major part due to Apple’s massive investment in factories, machines, and training of tens of millions of skilled workers over the past 15 years, as outlined in Patrick McGee’s Apple in China. We should not emulate China’s central planning model, but we can draw on elements of China’s strategy much as China copied us.

As we aim to advance and expand physical AI, quantum computing, and software-driven manufacturing technologies, we need a large-scale effort to ensure we have adequate workforce across the U.S. and our allies to actually build these products. We must fund trade schools, modern apprenticeships, and STEM programs that prioritize applied engineering. These are good jobs in critical industries and provide excellent long-term on-ramps for career growth.

These are not radical ideas. They are pragmatic, achievable, and urgent. The next generation of enduring American companies won’t be built on screen swipes and subscriptions. They will be the foundation of an entirely new economy. They will unite atoms, bits, and the American spirit of innovation. They will make us more productive, competitive, resilient, and safe.

Hardware isn’t just “hard”— it’s essential. The future of our country depends on whether we have the will to build it.

Follow Eclipse on LinkedIn or sign up for Eclipse’s Newsletter for the latest on building the New Economy